Corrugated Cardboard vs. Chipboard – Who Wins?

Using corrugated cardboard is definitely, in some cases, an eco-friendly solution that provides strength. However, we can do better than that by using chipboard. Not only does chipboard use less material, but it can also bear load capacities that are larger than corrugated cardboard.

So is using chipboard over corrugated cardboard really better? Let’s take a look at 3 detailed ways on how chipboard competes with and exceeds corrugated cardboard.

1. Inventory Space

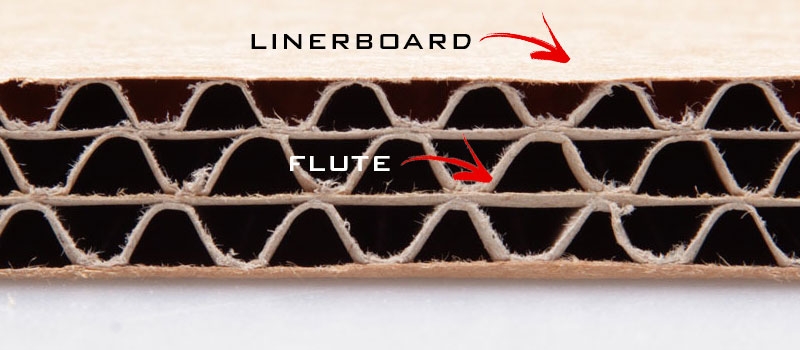

Corrugated cardboard is created by sandwiching a flute made of medium between two sheets of linerboard. This takes up a lot more space in your inventory.

Whether you’re using a single, double, or triple wallboard, you need your inventory to accommodate the space corrugated cardboard takes up. The most common corrugated cardboard is “C” flute and tends to be 5/32” or about 4 mm thick.

Chipboard is extremely straightforward in comparison. Wood fibers are used to create one layer of chipboard and can vary when it comes to thickness. For example, the common 40” x 48” chipboard pad is only .022 (22 pts).

So how does this directly translate to the amount of space used?

Guess which is corrugated cardboard or chipboard!

2. Cut Quality

Corrugated cardboard isn’t well known for its cut quality and looks rough to touch from a simple glance. The cut quality goes down even further after it’s been reused. Since we’re so used to this type of cut, we don’t expect that reused corrugated cardboard sheets will look any better over time.

Even a simple visit to your local hardware store will show you that cardboard won’t remain in working condition for very long.

On the other hand, take a look at our superior cut quality. You can easily see that our cutting machines provide the cleanest cuts for all sorts of grades and thickness, especially when they’re handled by certified operators.

It also helps that we get our chipboard from some of the best paper mills out there that we trust. Having just the right chipboard is important to getting that high quality cut.

Price Comparison

So you can see the amount of space used and the cut quality are great when it comes to chipboard. You might think that a superior product like chipboard would be more expensive for the value you’d be getting. Try answering the questions below and flip the boxes to see the answers.

Conclusion

Chipboard wins on every level when it comes to saving on inventory space, consistent yet superior cut quality, and price comparisons. When the perfect alternative exists, it’s time to think about switching to it or providing it as another option. There’s no reason not to if you want to put money back into your company.

Contact us today to get started on shifting to our better quality yet cost-efficient chipboard.